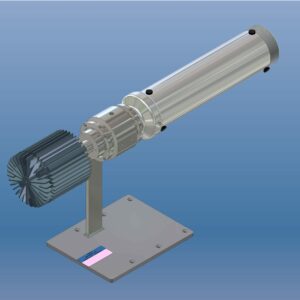

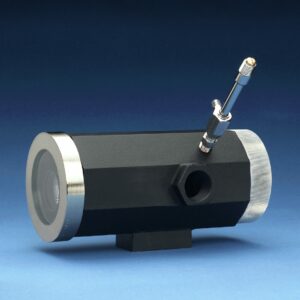

The Canty PHARMAFLOW™ has been engineered to analyze small volume samples for particle size, shape and concentration. The PHARMAFLOW™ easily converts from a lab unit to allow for continuous sampling in-line using sanitary Tri-Clamp™ connections. It offers microscopic, non-destructive viewing and provides particle size analysis with two dimensional results when used in conjunction with the CantyVisionClient™ Software. The vision system, with integral lighting, features precision optics designed to enhance the image prior to display or analysis. The image sensor is a high resolution / high speed CCD camera coupled to a microscopic lens system. The system offers zoom and focus ability, variable lighting, and multiple objective lens packages to cover a range of sizes. The PHARMAFLOW™ features the FUSEVIEW™ window as the flush product contact barrier which ensures laminar flow & eliminates pockets for potential product build-up. Sizing down to 0.7 micron is possible with the high magnification optics and high intensity light source. A variety of pumps can be used in conjunction with the system, including syringe style injection as well as peristaltic pumps.